- Home

- Benefits of Pultrusion Material vs. Other Materials

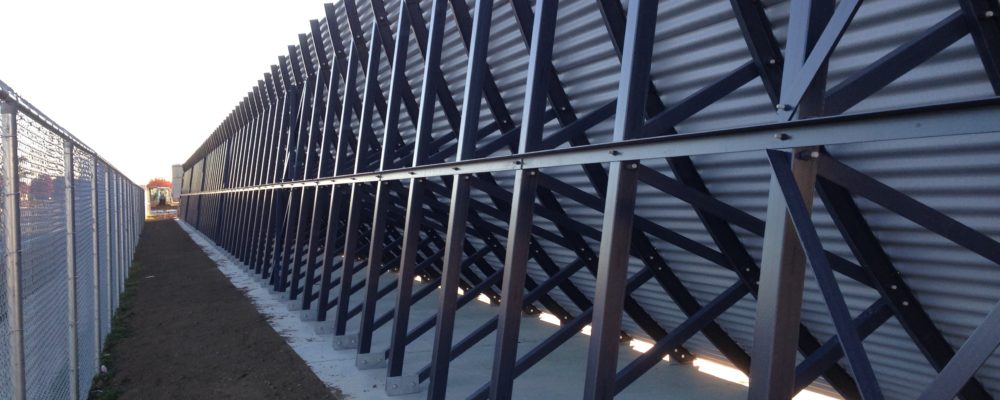

Fiber Reinforced Plastic (FRP) pultrusions are used in many types of applications throughout many different industries. The pultrusion process allows Liberty Pultrusions to produce continuous lengths of fiber reinforced polymer (FRP) profiled shapes.

Pultrusion material holds a lot of value over other types of materials that you may be considering for your next construction project or application.

Pultruded products are non-conductive

corrosion resistant, strong, durable and

lightweight, among other versatile

and cost-effective properties.

Depending on the class of polyglas structural pultrusion profiles, FRP pultrusion may also be made to be fire-retardant.

Polyglass electrical pultrusion has these same great properties and can also be manufactured as non-magnetic, UL listed, arc and track resistant and fire-retardant.

In comparison to metal and wood, pultrusions are much more lightweight (75% more lightweight than steel and 30% more lightweight than aluminum), which can make a tremendous difference in many industries including transportation, aerospace, sporting equipment and many others.

Another advantage is that steel, aluminum and other metals have isotropic properties, or equal strength in every direction. FRP Pultrusions on the other hand, can have applied reinforcement where it is needed, allowing for more efficiency.

Benefits of Pultrusion Over Wood / Structural Timber

The most obvious advantage of pultruded material over wood is that pultrusions will not rot, mildew, mold or warp due to weather or moisture exposure. They are also not at risk for insect infestation. And unlike wood when wet, FRP pultrusion is non-conductive, making it a much safer material for many types of applications.

Another key advantage is that pultrusion material is lighter in weight than structural timber, but at the same time pultrusion is still much stronger and more rigid.

Liberty Pultrusions Structural Composites have “built-in” ultraviolet and weather protection and are corrosion resistant. There is no need to apply costly coatings, preservatives or films, like you would need to if using wood.

Benefits of Pultrusion Over Steel

The three greatest benefits of pultrusion over steel are non-conductivity, corrosion resistance and being up to 75% more lightweight (even though pultrusion is just as strong or more so than steel on a pound for pound basis.) These properties make a tremendous impact on providing safety, lower long-term cost and better design, depending on the application you are supporting. Unlike steel, FRP pultrusion is non-conductive, both thermally and electrically.

With FRP pultrusion you get all of these benefits without the rust and cost of replacing corroded and oxidized materials due to weather, moisture and chemical exposure. Steel often requires painting or galvanizing to maintain. Because of this, pultruded material often has a lower life cycle cost than steel.

Another advantage is that FRP Pultrusion is transparent to radio waves and EMI/RFI transmissions. This often makes FRP pultrusion the optimal solution for many types of radio, radar and antenna applications.

In addition pultruded structural profiles can be fabricated with simple tools and does not require welders. Because pultrusion is lightweight, it is easier to install than steel and may not require special erection or lift equipment.

Depending on the resin option you choose, FRP pultrusion can also be made to be fire retardant. At Liberty Pultrusions, standard structural pultrusions come in three standard systems: Polyglas ‘F’, ‘C’ or ‘M’.

Benefits of Pultrusion Over Aluminum

While aluminum is heavier and has high thermal conductivity and high electrical conductivity, as well as low corrosion resistance, FRP Pultrusion is the opposite: lightweight, non-conductive (thermally and electrically) and highly corrosion resistant. FRP Pultrusion is approximately 30% lighter than aluminum.

Both aluminum and FRP Pultrusion are strong, but the dimensional stability of pultrusion is much higher. In addition, pultrusion are impact resistant and EMI/RFI transparent, whereas aluminum can easily dent and deform under impact and will interfere with transmissions.

The cost of aluminum may be comparable or even less than pultrusion, but because of corrosion and malleability of aluminum, the total long-term costs of pultrusion are less expensive. In addition, pultrusion may be a much safer option for many types of applications.

Key Advantages of FRP Polyglas Structural Pultrusion:

- Corrosion resistance

- Chemical resistance

- Non-conductivity (thermally and electrically)

- Having non-magnetic electromagnetic transparency

- Being lightweight

- High-strength & durability

- Impact resistant

- Dimensional stability

- A long life cycle

- Low-maintenance

Polyglas Structural Pultrusions Are Offered In Three Standard Systems

* Polyglas F = Fire retardant, polyester, gray color

General purpose composite manufactured in a fire retardant isophthalic polyester resin system. Standard colors are gray and hazard yellow.

* Polyglas C = Fire retardant, vinyl ester, beige color

A superior grade composite manufactured in a fire retardant and highly corrosion resistant vinyl ester resin system. Standard color is beige.

* Polyglas M = Non-fire retardant, polyester, olive color

General purpose composite manufactured with a non-fire retardant isophthalic polyester resin system. Standard color is olive green.

Key Advantages of Polyglas Electrical Pultrusion:

- Non conductive thermally and electrically

- Non-magnetic

- Electromagnetic transparency

- Lightweight

- High strength

- Dimensional stability

- Long life cycle

- Low maintenance

- UL listed

- Fire retardant

- Arc and track resistant