- Home

- Pultrusion Products

- Structural Pultrusions

We engineer and manufacture standard structural FRP shapes through the pultrusion process for use in many types of applications. We are a US-based manufacturer of pultrusions and have been a leader in the pultrusion industry for over 40 years.

FRP structurals incorporate features that translate into benefits for end users, fabricators and erectors.

Structural Pultrusions have a superior long-term resistance to chemical corrosion and other weathering. They will not rust, rot, scale or mildew.

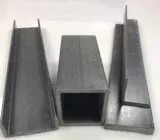

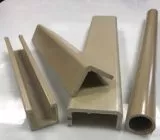

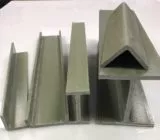

Structural Fiberglass Products come in several standard sizes and shapes and include:

Fiberglass Electrical Shapes

If we do not have the size and shape you need for your application, we also design and manufacture custom pultrusions. If you are unsure of what you need for your project, our expert engineers can help you.

BENEFITS OF STRUCTURAL PULTRUSIONS

FRP pultruded structurals are strong, durable, and have a high strength to modulus ratio.

Our Polyglas Structural Pultrusions are a combination of fiberglass reinforcements and thermo-setting polyester or vinyl ester resin systems. They are produced using a premium grade isophthalic fire-rated resin, which is superior in corrosion resistance to general-purpose resin systems.

All of our structural composites include a surface veil to protect against fiber blooming. It also increases the composites useable life cycle, corrosion resistance and ultraviolet resistance.

They are particularly effective in high impact conditions and repeated or cyclic loadings associated with windstorms. To see all the benefits, read about how pultrusion compares to other types of material.

Polyglas Structural Pultrusions Are Offered In Three Standard Systems

* Polyglas F = Fire retardant, polyester, gray color

General purpose composite manufactured in a fire retardant isophthalic polyester resin system. Standard colors are gray and hazard yellow.

* Polyglas C = Fire retardant, vinyl ester, beige color

A superior grade composite manufactured in a fire retardant and highly corrosion resistant vinyl ester resin system. Standard color is beige.

* Polyglas M = Non-fire retardant, polyester, olive color

General purpose composite manufactured with a non-fire retardant isophthalic polyester resin system. Standard color is olive green.

APPLICATIONS AND USES FOR STRUCTURAL PULTRUSIONS

FRP structural shapes are commonly specified by engineers and industrial designers for use as supports for FRP roofing and siding and as components in corrosive environments such as metal processing, wastewater treatment, pulp and paper, petrochemical, mining, etc. In many cases they have replaced more conventional materials which have proven to be costly and ineffective in corrosive environments.

Liberty Pultrusions produces structural fiberglass products for a variety of uses, products and applications across a large array of industries. Some of these include:

- Blast Deflector Shield

- Cooling Towers

- Conveyor Systems

- Bridge Hanger Communication Supports

- Retaining Walls

- Third Rail Coverboards / Transit

- Railway Crossing Gate Arms

- Solar Racking Systems

- Waste Water and Water Treatment Components

- Utility Cross Arms

- Utility Poles

- Sheet Pile

- Agricultural

- Chemical Plants (Corrosion)

- Docks

- Ladders

- Railings

- Pergolas

- Bridge Components

- Tarp Stiffeners

- Truck Components

- Corrosion Resistant Industrial Handrails

- Antenna Housing

- Building Construction

- Trash Gates

- Cellular

- Electric Utility

- Infrastructure

- Parks and Recreation

- Tool Handles

- Military

- Pulp and Paper Products